-

Standard: ISO Environmental ManagementNumber:Issue Date:Expiry Date:

-

Standard: ISO Quality ManagementNumber:Issue Date:Expiry Date:

-

Standard: CE-LVDNumber:Issue Date:Expiry Date:

-

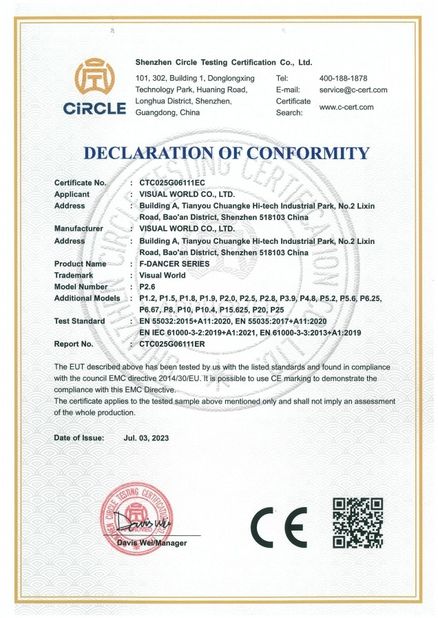

Standard: CE-EMCNumber:Issue Date:Expiry Date:

-

Standard: RoHSNumber:Issue Date:Expiry Date:

-

Standard: RoHSNumber:Issue Date:Expiry Date:

-

Standard: RoHSNumber:Issue Date:Expiry Date:

-

Standard: FCCNumber:Issue Date:Expiry Date:

Quality Control of LED Display

Worried about the quality of your LED display before making the final payment?

As a leader in the LED display industry, VISUAL WORLD has implemented a complete and rigorous quality control program to ensure that every aspect of the product's production process is carefully inspected. We will provide you with a detailed quality inspection form, accompanied by pictures and videos, so that you can rest assured. This rigorous approach ensures you get the highest quality LED display before final payment.

Below you will learn about the complete LED display quality control process.

Before LED Display production process

In order to ensure the quality of LED display, a complete quality control plan must be developed before production, which includes the selection of raw materials, inspection of product details with customer confirmation, and communication with the factory to ensure that the LED displays meet high standards.

![]()

LED Screen Panel Production Process

VISUAL WORLD follows stringent production processes and maintains clean production workshop standards. We provide comprehensive training for our employees to ensure adherence to production requirements and place a strong emphasis on quality inspection throughout the production process to guarantee the excellent quality of the final product.

![]()

After Finishing the Production

Understanding the diverse needs of our customers, VISUAL WORLD offers two thoughtfully designed packaging options: flight boxes and wooden boxes. Each option is tailored to provide maximum protection for your LED screen displays during transportation.

![]()